- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

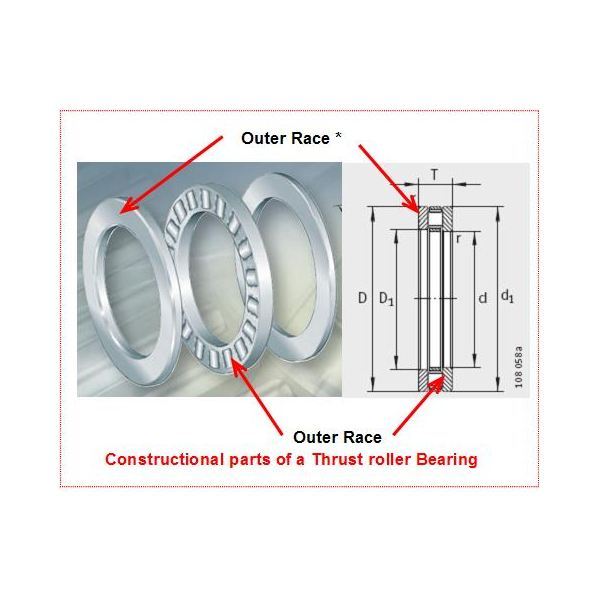

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Q: What is the application of thrust roller bearing?

A: Thrust roller bearings are separable bearings, which can only withstand unidirectional axial loads and slight impacts. They can limit axial displacement of the shaft (or housing) in one direction, so they can be used as unidirectional axial positioning. But its bearing capacity is far greater than thrust ball bearings. When the roller is rolling, due to the different linear speeds of the two ends of the roller, the roller inevitably slips on the raceway of the ring. Therefore, the limit speed of this type of bearing is lower than that of thrust ball bearings, and it is usually only suitable for low-speed operation. The standard design of thrust cylindrical roller bearings adopts metal solid cages made of cars. According to user requirements, other types of materials of cages can also be used. Thrust tapered roller bearings can only withstand unidirectional axial loads and can limit the unidirectional axial displacement of the bearings, so they can be used as unidirectional axial positioning.

Compared with thrust roller bearings, the bearing capacity is large and the relative sliding is small, but the limiting speed is low.

Thrust roller bearings are mainly used in machinery such as heavy machine tools, high-power marine gearboxes, petroleum rigs, vertical motors and so on.

The types of thrust roller bearings are metric thrust roller bearings, inch thrust roller bearings, stainless steel thrust roller bearings, thrust cylindrical roller bearings, thrust tapered roller bearings, etc.