- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Do You Know How to Do Bearing Fault Analysis 2020 [Works Quickly]

time2018/06/19

- Bearing fault diagnostics is critical for industrial safety and machine operations along with reducing the maintenance costs or avoiding shutdown time.

Do You Know How to Do Bearing Fault Analysis 2020 [Works Quickly]

What is the rolling-element bearing fault

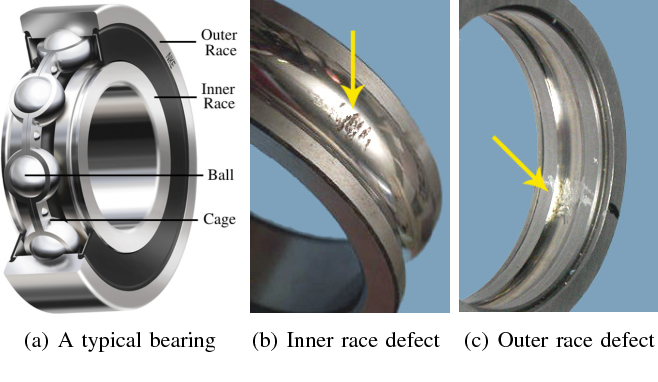

Rolling-element bearings have wide applications in the industries today, and these bearings maintenance becomes an important task for the maintenance professionals. The rolling-element bearings wear out easily due to metal-to-metal contact, which creates bearing faults in the outer race, inner race, and ball. It is also the most vulnerable component of a machine because it is often under high load and high running speed conditions.

Bearing fault regular diagnostics is critical for industrial safety and machine operations along with reducing the maintenance costs or avoiding shutdown time. Among the outer race, inner race, and ball, the outer race tends to be more vulnerable to faults and defects.

Bearing frequencies analysis

There is still room for discussion as to whether the rolling element excites the natural frequencies of the bearing component when it passes the fault on the outer race. Hence we need to identify the bearing outer race natural frequency and its harmonics. The bearing faults create impulses and results in strong harmonics of the fault frequencies in the spectrum of vibration signals. Adjacent frequencies in the spectra sometimes mask these fault frequencies due to their little energy. Hence, it needs a very high spectral resolution to identify these frequencies during an FFT analysis.

Bearing natural frequency

The natural frequencies of a rolling bearing with the free boundary conditions are 3 kHz. Therefore, in order to use the bearing component resonance bandwidth method to detect the bearing fault at an initial stage. You should adopt a high-frequency range accelerometer. And you may obtain data from a long duration. Identify a fault characteristic frequency when the fault extent is severe, such as that of the presence of a hole in the outer race.

Bearing harmonics frequency

The harmonics of fault frequency is a more sensitive indicator of a bearing outer race fault. For a more rigorous bearing failure detection, you should detect waveform, spectrum, and envelope techniques. And these will help reveal these faults. However, if you use high-frequency demodulation in the envelope analysis in order to detect bearing fault characteristic frequencies. The maintenance professionals have to be more careful in the analysis because of resonance. Because it may or may not contain fault frequency components.