- Home

- About us

- Products

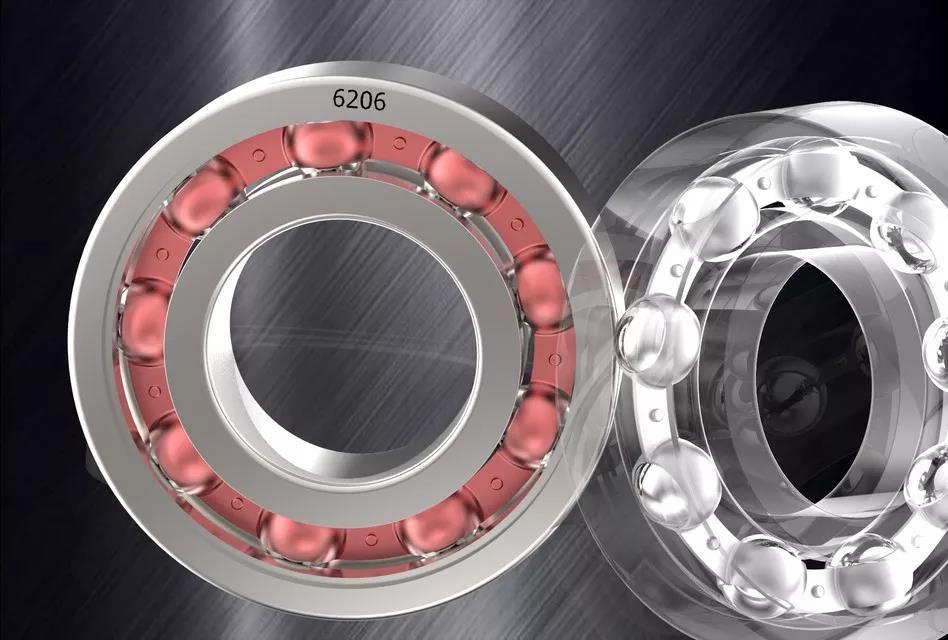

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

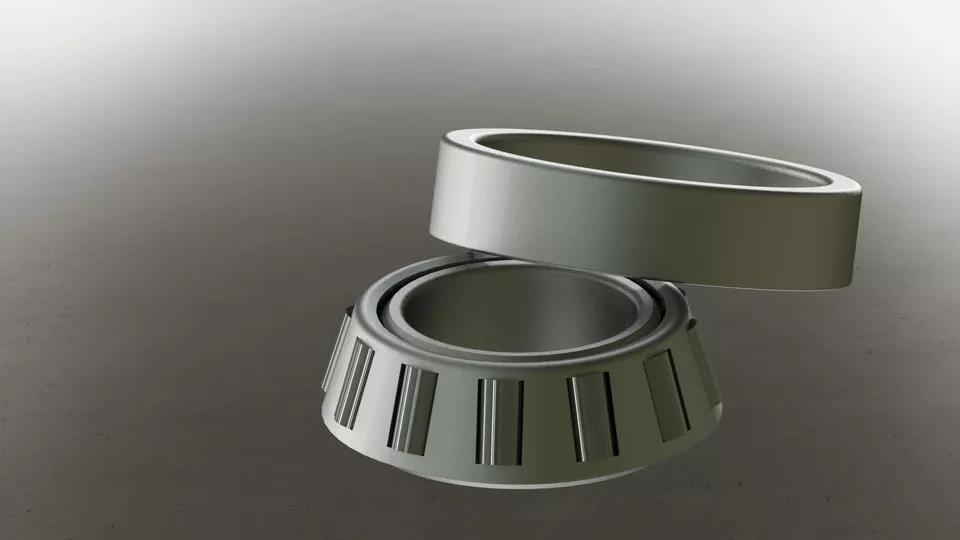

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

9 Keys of How to Choose Proper Type of Bearing for Your Application

time2018/08/15

- " Various type of bearing has different characteristics due to different designs. Due to the bearing's specific location of installation.

9 Keys of How to Choose Proper Type of Bearing for Your Application

" Various type of bearing has different characteristics due to different designs. Due to the bearing's specific location of installation and the variability and complexity of the application, you can use bearing type selection without fixed mode to adapt to a certain host-specific location of installation and application conditions for bearing selection. It's better to take comprehensive consideration according to the following main factors."

Allow space of various type of bearing

Bearing mechanical design, generally determine the size of the shaft first and then choose the bearing according to the size of the shaft. Generally, small shafts use ball bearings. Big shaft uses cylindrical roller bearings, centering roller bearings, and tapered roller bearings. If there is limited radical space of bearing mounting position, you should use bearings with smaller radial section height. Such as needle roller bearings, certain series deep groove ball bearings, angular contact ball bearings, cylindrical or centering roller bearings, and thin-wall bearings. If there is limited axial space of the bearing mounting position, it's better to use the bearing with a smaller width.

Bearing load

The load size is usually the determinant of the bearing size. The bearing capacity of a roller bearing is larger than that of ball bearing with the same dimension. People use ball bearings for light or medium loads and roller bearings for heavy loads.

Pure radial loads use deep groove ball bearings and cylindrical roller bearings. Select thrust ball bearing and thrust cylindrical roller bearing for the pure axial load. Angular contact ball bearings or tapered roller bearings are commonly used when radial and axial loads are available. If the radial load is large and the axial load is small. you can select deep groove ball bearings and cylindrical roller bearings with inner and outer rings with baffles.

At the same time, the shaft or shell deformation is large and the mounting pair is neutral, you can select adjustable ball bearings and roller bearings. If the axial load is large and the radial load is small, it's better to select the thrust angular contact ball bearing. If four-point contact ball bearing still requires centering performance, the thrust adjusting roller bearing is the first choice.

Bearing speed

The working speed of the rolling bearing mainly depends on the allowable operating temperature. Bearing with low friction resistance and less internal heat is suitable for high-speed operation. When only bearing radial load, deep groove ball bearing and cylindrical roller bearing can reach high speed. If bearing combined load, angular contact ball bearing should be selected. Special designed high precision angular contact ball bearing can achieve high speed. The speed of all kinds of thrust bearings is lower than that of radial bearings.

Rotation accuracy

For the majority of machinery, choose a level 0 tolerance of bearing is enough to meet the requirements of the host, but on the axis of rotation, accuracy has strict requirements. Such as the spindle, precision machinery, and instrument, etc. You should choose high tolerance grade of deep groove ball bearings, angular contact ball bearings, tapered roller bearings, cylindrical roller bearings, and thrust bearings.

Rigidity

The elastic deformation determines the rigidity of rolling bearing under load. Generally, such deformation is very small and can be neglected. However, in some machines, such as the machine tool spindle system, static and dynamic stiffness of bearings have a great influence on the system characteristics. Roller bearings have higher stiffness than ball bearings. Properly "preload" various types of bearings to increase stiffness to varying degrees.

Noise and vibration

The noise and vibration of the bearing itself are generally very low. However, for small and medium-sized motors, office machines, household appliances, and instruments that have special requirements for noise and smooth operation. You should choose low-noise bearings.

The axial moving

The most common way to configure bearings is to install a set of shaft-oriented "identical bearings" at one end of the shaft. And install a set of axially "movable bearings" at the other end to prevent sticking due to the shaft expansion and contraction. The commonly used "floating bearing" is the cylindrical roller bearing with an inner ring or outer ring without baffle. At this time, adopt the matching of the inner ring and shaft or the matching of the outer ring and outer ring. Sometimes, select in-separable deep groove ball bearings or centering roller bearings as floating bearings. But select clearance fit for the inner ring and shaft or outer ring and outer hole during installation. Make sure that the inner-ring or outer ring has enough freedom of axial movement.

Friction torque

The friction resistance of ball bearing is smaller than that of roller bearing. When you need the axial load, the friction resistance of the axial contact bearing is small. When you use the combined load, the friction resistance of bearing contact angle is the least. Ball bearings or cylindrical roller bearings are more suitable for equipment and machinery where is require low friction torque. In addition, the low friction torque bearing should avoid using the contact seal. At the same time, you should use drip lubrication, oil, and gas lubrication, or other lubrication methods that are conducive to wear reduction.

Installation and removal

Rolling bearings with cylindrical inner bore are used for mounting and disassembling the machines frequently, the separation of angular contact ball bearings, taper roller bearings, detachable cylindrical roller bearings, needle roller bearings, and thrust bearings. Bearings with conical bore can be mounted on the journal, or on the cylindrical journal by means of a tightener or back-off sleeve.