- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Complete Analysis on What are Automobile Ball Bearings [Quick]

time2019/08/15

- Both in industrial life and in private life, automobile ball bearings keep vehicles functioning correctly ‒ avoiding friction.

Complete Analysis on What are Automobile Ball Bearings [Quick]

Both in industrial life and in private life, ball bearings keep vehicles functioning correctly ‒ avoiding friction and supporting both radial and axial loads. Automobile ball bearings appear in everything from wheels to turbochargers. And automobile ball bearings are particularly important in vehicles because they help counteract the effects of inertia.

Read more below to find out more about how these widely used engineering components work in automobiles.

Ball Bearings In The Car Industry

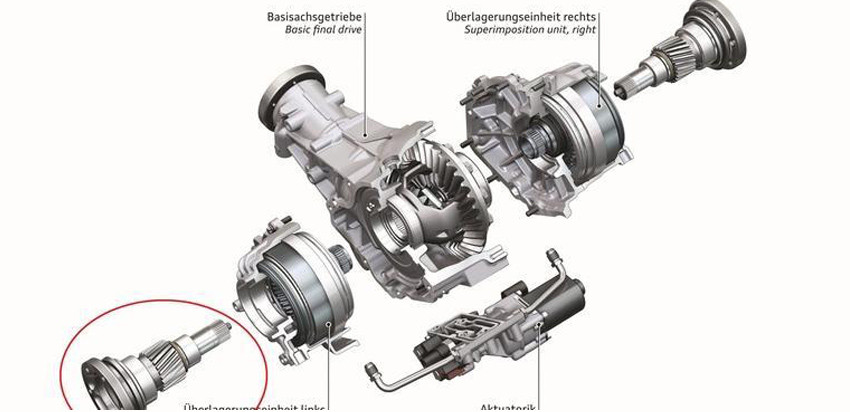

A ball bearing is a type of roller bearing, comprised of inner and outer raceways, with hollow steel or ceramic balls between them. The balls allow the transmission of loads, which in turn reduces friction between two surfaces, such as in the case of a vehicle and the road. Because ball bearings are able to support axial and radial loads, it allows vehicles to maintain balance during sudden braking, turning on sharp corners, and during speed changes.

Ceramic ball bearings are popular in the automotive industry because they are heat resistant, which makes them perfect for applications such as turbocharged engines. Besides thrust bearings and plain bearings, ball bearings are the most widely used bearing in the automotive industry.

Bearings in Automotive Parts

- Petrol and turbocharged engines

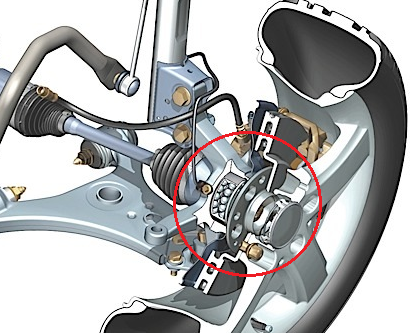

- Suspension systems

- ABS systems

- Wheels

- Crankshafts

- Axle shafts

- Driveshafts

- Alternator

- Radiators

With so many vehicle parts relying on well-functioning ball bearings, the manufacturing process for these components is stringent. On its way to completion, ball bearings go through no less than five quality checks - ensuring that the raceways and balls are free from any defects and are precisely the right shape and size. To avoid downtime or accidents, always ensure that you avoid purchasing fake bearings. Fake bearings often have the trademark of trusted brands but without the guaranteed quality.