- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

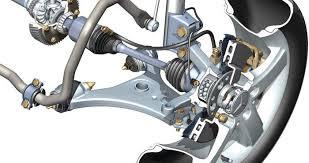

Useful Reviews about Why Do Axle Bearing Noise? [Right Now]

time2019/11/22

- Axle bearing noise that people often ignore a problem bearing operation process. Therefore, bearing noise problems are likely to ruin your machinery.

Useful Reviews about Why Do Bearings Make Noise? [Right Now]

As we all know bearing has huge wide applications, however, people often ignore a problem bearing operation process---axle bearing noise. Therefore, axle bearing noise problems are likely to ruin your machinery.

For example, my friend’s car has an axle bearing noise problem in front-wheel but he didn’t notice, as a result after he drove 30 minutes he felt the noise louder and got out of the car to check when he touched the wheel hub part there was a little hot. So he had to send the car to repair. Then he told me that this fault almost damaged his axle.

So this article summarizes all the reasons why do axle bearings make noise which will be very useful for you.

Some Reasons Axle Bearing Noise

Excitation due to the change in the number of loaded rolling elements

When a bearing applies radial load, the number of rolling elements carrying the load changes slightly during operation, causing a shift in the load direction.

Partial damage

Handling or installation errors will damage small parts of the bearing raceways and rolling elements. In operation, damaged bearing components produce a specific vibration frequency. Vibration frequency analysis identifies damaged bearing components. We also apply this principle to condition monitoring equipment to monitor bearing damage.

Accuracy of related parts

When the inner and outer rings of the bearing are in close coordination with the bearing box or drive shaft, the shape of the adjacent components that may deform the inner and outer rings of the bearing improperly. If deformation occurs, vibration and noise may occur during operation.

Contaminants

If operating the equipment in a polluted environment, impurities may enter the bearing rolling elements to produce a vibrating sound. This kind of situation can usually hear annoying noises.

Other

The causes of rolling bearings generate noise that is more complicated. One is the wear of the inner and outer rings of the bearing. Due to this wear, the bearing and the housing, it will break the bearing and the shaft. Causing the axis to deviate from the correct position. The shaft produces an abnormal sound when moving at high speed.

In addition, insufficient bearing lubrication, dry friction, and bearing crushing can produce abnormal sounds. If the bearing is wear and tear and the cage is loose and damaged, abnormal noise will also occur.

Different Bearings Have Different Noise Levels?

- The noise of the ball bearing is lower than that of the roller bearing. The (friction) noise of the bearing with less sliding is lower than that of the bearing with relatively more sliding; if the number of balls is large, the outer ring is thick and the noise is small;

- The noise of the use of the solid cage bearing is relatively lower than that of the bearing using the stamped cage;

- The noise of the plastic cage bearing is lower than that of the bearings using the above two cages;

- Bearings with high precision, especially those with higher precision of rolling elements, have lower noise than low-precision bearings;

- Compare with the noise of large bearings the noise of small bearings is relatively small.

Of course, this is theoretically the case. In practice, the size of the noise has many factors combined.

Experts Say 30 Reasons for Bearing Noise

- Grease has impurities;

- Broken bearing cage;

- The bearing raceway is rusty;

- The bearing is noisy (with external source interference);

- Unqualified ferrule raceway (manufacturer problem);

- The clearance of the bearing is too small or too large (manufacturer problem);

- The diameter of the seat hole is too small (causing the bearing temperature to be too high);

- The seal is eccentric (wearing adjacent parts and rubbing);

- There are debris in the housing bore (residues, dust, etc.);

- The bearing is noisy (the end face of the roller or the slip of the steel ball);

- The shoulder is too large (the seal of the bearing is encountered and friction occurs);

- The clearance of the labyrinth seal is too small (friction with the shaft);

- The teeth of the lock washer are bent (wearing the bearing and rubbing);

- The shoulder of the seat hole is too large (deformation of seal on bearing);

- The position of the oil ring is not suitable (the flange cover has friction occurs);

- Mix the bearing with impurities such as sand or carbon particles to act as an abrasive;

- Steel ball, raceway wear (unqualified grinding or product scratches);

- The thermal elongation of the shaft is too large (The bearing bears a static axial load);

- The seat hole flatten the bearing (the roundness of the seat hole is not good, or the seat hole doesn't twist straight);

- There are moisture, acid or paint and other dirt on the bearing surface, which acts as a corrosive effect;

- The coupling between the bearing and the shaft is too loose (the diameter of the shaft is too small or the adapter sleeve is loose);

- The clearance of the bearing is too small, too tight when rotating (the tightening sleeve is too tight);

- There is a crater on the steel ball or roller (because of hammering the bearing during installation);

- The bearing is discolored and deformed by heat (caused by the use of a spray gun to disassemble the bearing);

- The shaft is too thick to make the actual fit too tight (causing the bearing temperature to be too high or noise);

- Insufficient lubrication (oil level is too low, improper storage causes oil or grease to leak through the seal);

- The horn of the bottom of the bearing housing is not flat (resulting in deformation of the seat hole or even cracking of the bearing housing);

- The diameter of the bearing housing hole is too large, and the actual fit is too loose (the bearing temperature is too high and the outer ring is slippery);

- The bearing housing hole becomes larger (the housing hole of non-ferrous metal is enlarged or enlarged due to thermal expansion);

- The bearing bears additional loads (tighten the bearing axially or there are two fixed end bearings on one shaft);