- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Rolling Element Bearing VS Plain Bearing How Do You Choose [Quick]

time2020/03/20

- Rolling element bearing vs plain bearing, bearings have two main types which are rolling friction bearings and sliding friction bearings.

Rolling Element Bearing VS Plain Bearing How Do You Choose [Quick]

Rolling element bearing vs plain bearing, how to choose has become a hot topic on the internet. This essay will tell you how to choose the two type bearing. Bearings are indispensable and important parts of mechanical products and play an important role in supporting the rotating shaft.

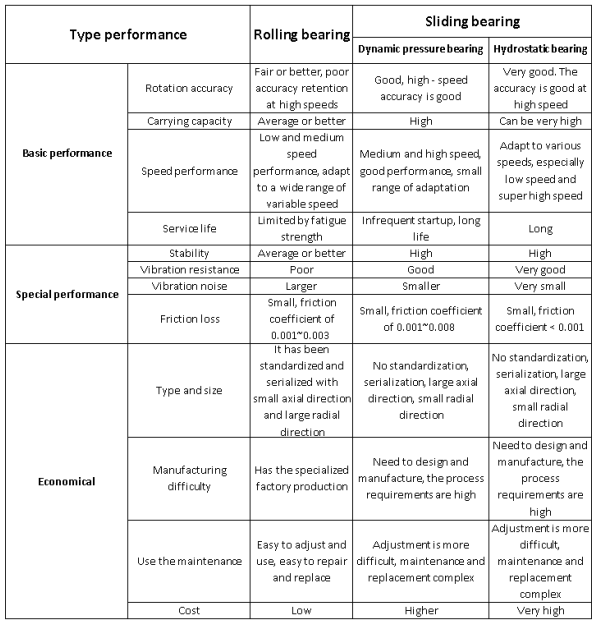

The two types of bearings have their own characteristics in structure and advantages and disadvantages in performance. When selecting, they must be considered in combination with actual conditions. The following compares and analyzes the specific performance of rolling bearings and plain bearings.

Comparison of structure and movement

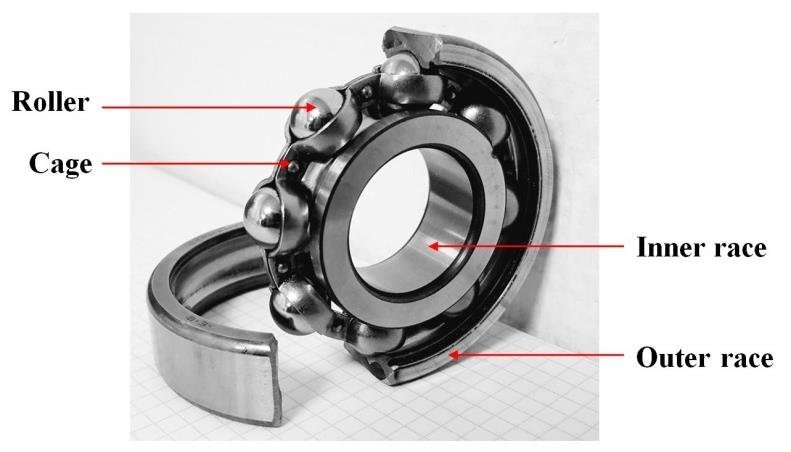

The most obvious difference between rolling and plain bearings is the presence of rolling elements.

Rolling bearings: There are rolling elements (balls, cylindrical rollers, tapered rollers, needles), which support the rotating shaft by their rotation, so the contact point is a point. The more rolling elements, the more contact points.

Sliding bearing: There is no rolling element, and a smooth surface supports the rotating shaft, so the contact part is a surface.

The difference between the two structures determines that the rolling bearing's moving mode is rolling, and the sliding bearing's moving mode is sliding, so the friction situation is completely different.

Carrying capacity comparison between rolling bearing and sliding bearing

Generally speaking, due to the large bearing area of the sliding bearing, its bearing capacity is generally higher than that of the rolling bearing, and the rolling bearing's ability to withstand impact loads is not high. Large shock loads. When the rotation speed is high, the centrifugal force of the rolling elements in the rolling bearing increases. And reduce its bearing capacity (prone to noise at high speed). For dynamic pressure plain bearings, its bearing capacity increases with increasing speed.

Comparison of friction coefficient and starting friction resistance

Under normal operating conditions, the friction coefficient of rolling bearings is lower than that of sliding bearings, and the values are relatively stable. The lubrication of sliding bearings is easily affected by external factors such as speed and vibration, and the friction coefficient varies widely.

When starting, because the sliding bearing has not formed a stable oil film, the resistance is greater than the rolling bearing. But the starting frictional resistance and working friction coefficient of the hydrostatic sliding bearing are very small.

Comparison of applicable working speed

The centrifugal force of the rolling elements and the temperature rise of the bearings limit rolling bearings, so the rotation speed cannot be too high. They are generally suitable for medium and low-speed working conditions. Incomplete liquid lubricated bearings due to bearing heating and wear, the bearing working speed should not be too high. The high-speed performance of completely liquid-lubricated bearings is very good. Especially when the static pressure sliding bearing uses air as a lubricant, its speed can reach 100,000r / min.

Power loss comparison

Due to the small friction coefficient of rolling bearings, the power loss is generally not large, which is smaller than that of incomplete liquid lubricated bearings. But it will increase sharply when lubrication and installation are improper. The frictional power loss of fully liquid lubricated bearings is low. But for hydrostatic sliding bearings, due to the power loss of the oil pump, the total power loss may be higher than the dynamic pressure sliding bearings.

Comparison of service life between rolling bearing and sliding bearing

Rolling bearings are affected by pitting and fatigue of materials, so the general design life is 5 ~ 10 years or replacement during overhaul. Incomplete liquid lubricated bearings are severely worn and need to be replaced regularly. The life of fully liquid lubricated bearings is theoretically unlimited. In fact, due to stress cycles, especially dynamic pressure sliding bearings, the bearing material may suffer fatigue damage.

Comparison of sliding bearing rotation accuracy

Due to the small radial clearance of rolling bearings, the rotation accuracy is generally high. Incomplete liquid lubricated bearings are in the state of boundary lubrication or mixed lubrication. The operation is unstable, the wear is serious, and the accuracy is low. Completely liquid lubricated bearings have high accuracy due to the presence of oil film, buffer vibration absorption. Hydrostatic sliding bearings have higher rotation accuracy.

Compared with other aspects of sliding bearings

Rolling bearings use oil, grease or solid lubricants, and the amount is small, and the amount is large at high speed. The cleanliness of the oil is high, so the seal is required. However, the bearing is easy to replace and generally does not need to repair the journal. For sliding bearings, except for incomplete liquid lubricated bearings. The lubricant is generally liquid or gas, the amount is large, the oil cleanliness requirements are high. The bearing bush needs to be replaced frequently, and sometimes the journal is also repaired.