- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

What Are The Influencing Factors of Bearing Life Expectancy

time2020/08/10

- There are many factors that affect bearing life expectancy. For example, the installation, disassembly, and maintenance of the bearing.

What Are The Influencing Factors of Bearing Life Expectancy

Bearing installation for bearing life expectancy

(1) Clean the bearing and its related parts;

(2) Check the size and finishing of related parts;

(3) Installation (just before opening the bearing package);

(4) Inspection after bearing installation;

(5) Supply lubricant.

General bearing grease lubrication, do not clean, directly filled the bearing with grease. Lubricating oil is enough to lubricate, and cleaning is not usually necessary. However, the bearings for instruments or high-speed applications you should wash them with clean oil to remove the rust inhibitor coated on the bearings. Bearings without rust inhibitor are easy to rust, so you should not leave them alone. In addition, you can use bearings with grease seal directly without cleaning.

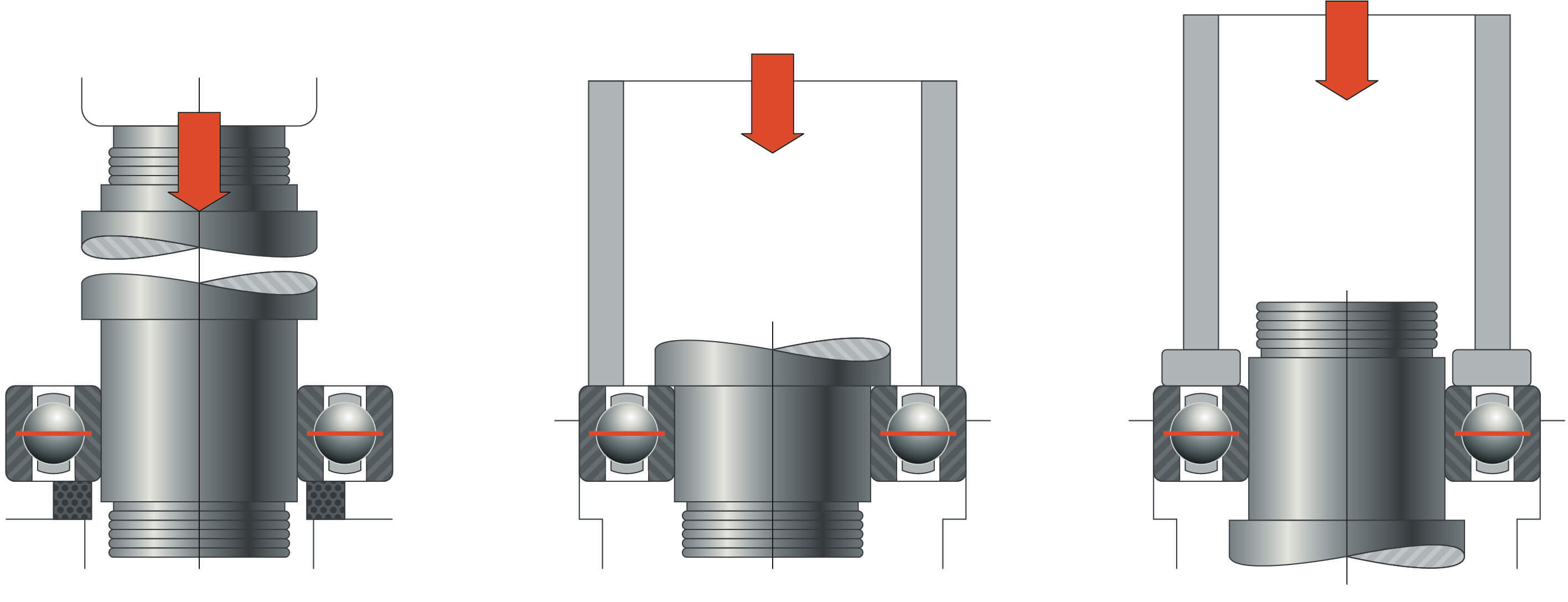

The installation method of the bearing varies according to the bearing structure and matching conditions. Generally speaking, since most shafts rotate, the inner ring needs an interference fit. Use a press or hot-fitting method to press bearings with cylindrical bores. In the case of a tapered hole, install it directly on the tapered shaft or use a sleeve.

Disassembly of the bearing for bearing life expectancy

The disassembly must follow the basic rules, and different disassembly tools and disassembly methods for different bearings. When the bearing and the shaft are in a tight fit, and the seat hole is in a loose fit, remove the bearing and the shaft from the housing together, and then remove the bearing from the shaft with a press or other removal tools.

Here are some common methods of bearing disassembly:

1. Disassembly of the outer ring

Remove the outer ring of the interference fit. Set several screws for the outer ring extrusion screw on the circumference of the housing in advance. Tighten the screw evenly while removing it.

These screw holes usually have blind plugs covers. Separable bearings such as tapered roller bearings. There are several cuts on the shoulder of the housing. Use spaces to remove them with a press or gently tap them.

2. Disassembly of the inner ring

Use a press machine to remove the inner ring. At this time, pay attention to let the inner ring bear its pulling force. Furthermore, no matter what kind of fixture, you must firmly clamp it to the side of the inner ring. For this reason, it is necessary to consider the size of the shoulder of the shaft or study the processing of the upper groove at the shoulder in order to use the drawing fixture.

The oil pressure method is better to use for the inner ring disassembly of large bearings. Apply the oil pressure is through the oil hole provided in the bearing to make it easy to draw. For bearings with a large width, the hydraulic method and the drawing fixture are used together for disassembly.

Induction heating can be used to disassemble the inner ring of cylindrical roller bearings. A method of heating the part in a short time to expand the inner ring and then drawing. Where a large number of these bearing inner rings need to be installed, induction heating is also used.

3. Unloading

The knock-off is a simple and common method of disassembly. It is a method to achieve the purpose of disassembly by using the power of hammering to displace the mating parts and separate them from each other.

Commonly used tools for demolition are hand hammers, that is, ordinary fitter's hand hammers, punches, and spacers.

When unloading, different methods and steps should be taken according to different machine structures:

Sliding bearing bushings and rolling bearing jackets are interference fit in the holes, and the method of removing them from the holes is also commonly used. When unloading, the hammered end face of the bushing should be cushioned. When unloading a small-diameter bush, it is better to use a stepped punch. The small diameter of the punch fits with the inner hole of the bushing. The large diameter of the punch is about 0.5mm smaller than the outer diameter of the bushing.

For the disassembly of large-diameter bushes and rolling bearings, casings are often used.

The disassembly of ordinary small bearing caps often adopts the method of symmetrically driving the inclined pads to open the bearing caps