- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

3 Methods on How to Check Reusable Bearing [Quick]

time2020/09/02

- Judging the reusable bearing. Inspect the bearings that were disassembled during the regular maintenance of the equipment, operation inspection.

3 Methods on How to Check Reusable Bearing [Quick]

Judging the reusable bearing. Inspect the bearings that were disassembled during the regular maintenance of the equipment, operation inspection, and replacement of peripheral parts. Carefully investigate and record the dismantled bearings and their appearance. To find out and investigate the remaining amount of lubricant. After sampling, clean the bearings well.

Secondly, check the raceway surface, the condition of the rolling surface, and the mating surface. And the wear state of the cage for damage and abnormal conditions.

Reusable bearing standard

To judge whether they are reusable bearings, it's necessary to consider the degree of bearing damage, machine performance, importance, operating conditions, inspection cycle, etc. before making a decision. If the inspection results reveal that the bearing has damage or abnormal, find out the cause and formulate countermeasures.

In addition, the inspection results show that if there are the following defects, you can not use this bearing anymore, and you need to replace a new bearing.

- 1. There are cracks and fragments in any of the inner and outer rings, rolling elements, and cage.

- 2. Anyone of the inner and outer rings and rolling elements has peeled off.

- 3. The raceway surface, ribs, and rolling elements are significantly scar.

- 4. There is severe cage wear or the rivets are loose.

- 5. The raceway surfaces and rolling elements are rusty.

- 6. There are significant indentations and marks on the rolling surface and rolling elements.

- 7. Creep on the inner diameter surface of the inner ring or the outer diameter of the outer ring.

- 8. The discoloration is severe due to overheating.

- 9. The seal ring and dust cover of the grease-sealed bearing have serious damage.

Inspection and troubleshooting during operation to check reusable bearing

The inspection items during operation include rolling sound, vibration, temperature, lubrication state of the bearing, etc.

The details are as follows:

Bearing rolling sound

Use a sound meter to check the size and sound quality of the rolling sound of the bearing in operation. Even if the bearing is slightly damaged such as peeling, it will emit abnormal and irregular sounds, which can be distinguished by a sound detector.

Bearing vibration

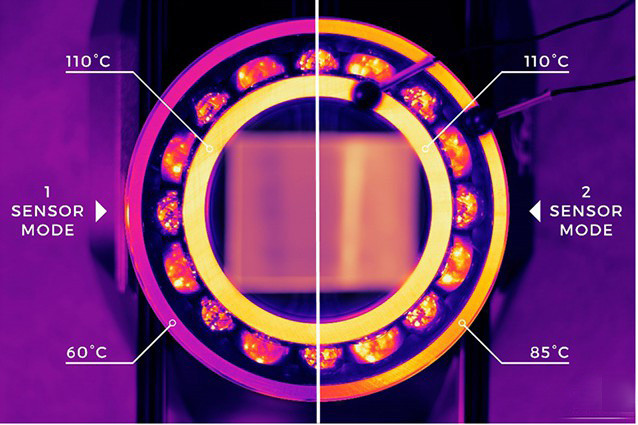

Bearing vibration is very sensitive to bearing damage, such as peeling, indentation, rust, cracks, wear, etc. the bearing vibration measurement will reflect them. Therefore, the magnitude of the vibration can be measured by using a special bearing vibration measuring device (frequency analyzer, etc.). Frequency points can not infer the specific circumstances of the abnormality. The measured value varies depending on the use condition of the bearing or the installation position of the sensor, etc. Therefore, it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

Bearing temperature

Generally, infer the temperature of the bearing from the temperature outside the bearing. It is more appropriate if you can use the oil hole to directly measure the temperature of the bearing outer ring. Generally, the temperature of the bearing slowly rises as it starts to run, and reaches a steady-state after 1-2 hours.

The normal temperature of the bearing varies with the heat capacity, heat dissipation, speed, and load of the machine. If the lubrication and installation are improper, the bearing temperature will rise sharply and abnormally high temperatures will occur. At this time, you must stop the operation and take the necessary precautions.

You can use the thermal sensor to monitor the operating temperature of the bearing. And realize that when the temperature exceeds the specified value, it will automatically alarm the household or stop to prevent the burning shaft accident.