- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Complete Instruction on How to Use Tapered Roller Bearing

time2020/11/18

- The tapered roller bearing is mainly bear combined radial and axial loads based on radial directions. Bearing capacity depends on the raceway angle.

Complete Instruction on How to Use Tapered Roller Bearing

The tapered roller bearing is mainly bear combined radial and axial loads based on radial directions. The bearing capacity depends on the raceway angle of the outer ring, the larger the angle, the greater the bearing capacity. Tapered roller bearings are separable bearings, including single-row, double-row, and four-row tapered roller bearings.

You should adjust the clearance of single row tapered roller bearings the user during installation. The factory will set the clearance of double-row and four-row tapered roller bearings according to user requirements.

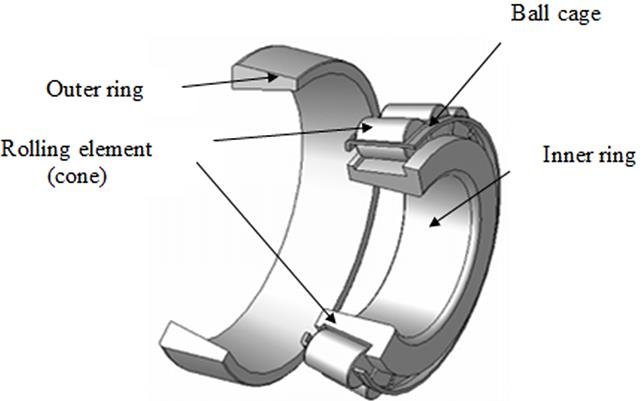

What is the tapered roller bearing

Tapered roller bearings have tapered inner ring and outer ring raceways, with tapered rollers. The projection lines of all cone surfaces converge at the same point on the bearing axis. This design makes tapered roller bearings particularly suitable for bearing compound (radial and axial) loads. Mostly, the contact angle α determines the bearing axial load capacity. The larger the α angle, the higher the axial load capacity. The calculation coefficient e represents the angle size. Therefore, the greater the e value, the greater the contact angle, and the greater the applicability of the bearing to bear axial load.

Tapered roller bearings are separable bearings, that is, the tapered inner ring assembly consisting of the inner ring with roller and cage. You can install the inner ring and outer ring separately.

Installation

Tapered roller bearings have wide application in industries such as automobiles, rolling mills, mining, metallurgy, and plastic machinery. The secondary reason why tapered roller bearings are showing scars during installation. When you assemble the bearing, the inner and outer rings of the bearing are skewed.

Although the quality of tapered roller bearings and other aspects are relatively good, rolling bearings are precision parts, and you must carry out accordingly. No matter you use how high-performance bearings if you use them improperly, the bearing won't have high performance.

Precautions for the use of tapered roller bearings

(1) Keep the taper roller bearing and its surroundings clean.

Even small dust invisible to the eyes can have a bad effect on the bearing. Therefore, keep the surroundings clean to prevent dust from entering the bearing.

(2) Use with caution.

A strong impact on the tapered roller bearing during use can cause scars and indentations, which can cause accidents. In severe cases, it will crack or break, so be careful.

(3) Use appropriate operating tools.

Avoid replacing with existing tools, you must use appropriate tools.

(4) Pay attention to the corrosion of tapered roller bearings.

When handling bearings, sweat on your hands can cause rust. Pay attention to the operation with clean hands, it is best to wear gloves as much as possible.