- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Complete Information on What Are Joint Bearings

time2021/03/23

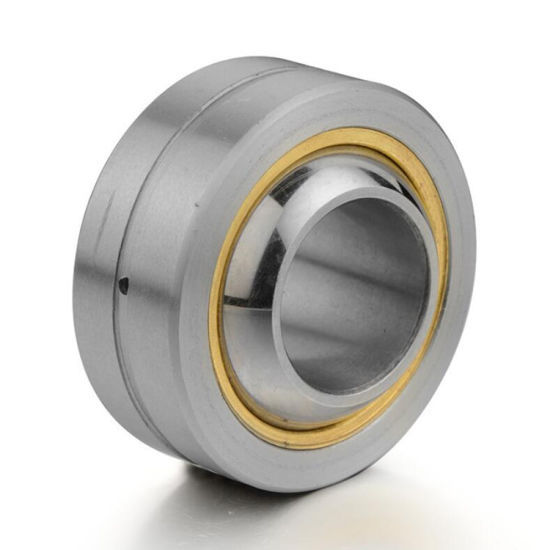

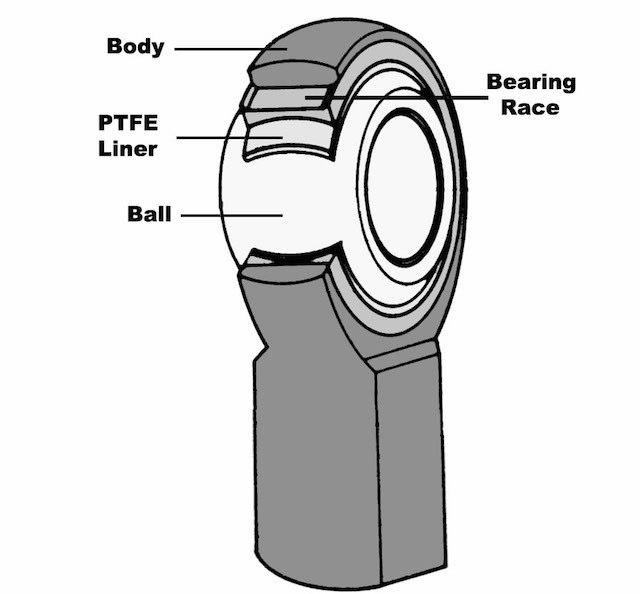

- Joint bearings are spherical plain bearings. Its sliding contact surface is an inner spherical surface and an outer spherical surface.

Complete Information on What Are Joint Bearings

The characteristics of joint bearings

Joint bearings can withstand larger loads. Therefore, according to its different types and structures, it can bear radial load, axial load, or a combined load of both radial and axial. Since the outer spherical surface of the inner ring is composite materials, the bearing can generate self-lubrication during operation.

Generally, people use it for low-speed swing motion and low-speed rotation. It can also have tilt movement within a certain angle range. It can still work normally when the supporting shaft and the shaft shell hole have a large degree of misalignment.

Application

The composition of the joint bearing

Maintenance method

Since the structure and working mechanism of the joint bearing are completely different from that of the rolling bearing, the joint bearing has its own technical characteristics and maintenance requirements.

Operating temperature

The matching material between the sliding surfaces of the bearing determines the allowable operating temperature of the joint bearing. Especially the sliding surface of plastic material of self-lubricating joint bearing, its carrying capacity will decline at high temperature. For all lubricating and self-lubricating joint bearings, people can use them in the temperature range of -30℃~+80℃ and maintain the correct bearing capacity.

Inclination

The inclination angle of the joint bearing is much larger than that of the general adjustable rolling bearing. Very suitable for use in supporting parts with low concentricity requirements. The inclination angle of the joint bearing varies with the size, type, sealing device, and support a form of the bearing. Generally, the inclination range of radial joint bearings is 3°~15°. The inclination range of angular contact joint bearings is 2°~3°. The inclination range of thrust joint bearings is 6°~9°.

Installation and removal

The installation and disassembly of joint bearings should follow the following principles.

(1) The force you apply during assembly and disassembly cannot be directly transmitted through the spherical sliding surface.

(2) In addition, you should use the correct auxiliary tools, such as sleeves, detachers, etc.

(3) You have to apply the externally applied loading and unloading force directly and evenly to the matching ferrule. Or use auxiliary methods such as heating to load and unload without load.

Installation

When assembling the joint bearing series, it is necessary to pay special attention to the position of the outer ring dividing surface. To prevent the load from directly acting on the dividing surface, it is necessary to maintain the dividing surface at a right angle to the coincident direction.

Lubrication

When the load and the speed of the swing movement are very small, the oil-feeding joint bearing can operate without bearing lubrication. Nevertheless, under normal circumstances, you must regularly add grease to the bearing. In the initial installation and operation, you need to moderately shorten the lubrication cycle.

Oil-free joint bearings can run without lubrication. However, if you add lithium soap-based grease before the operation, you can extend the life of the spherical plain bearing. If you inject grease into the space around the bearing, the joint bearing will be more effective in preventing the intrusion of dust and foreign matter.