- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Complete Information You Want to Know about 7MW Offshore Wind Power Main Shaft Bearings

time2021/10/27

- The technology of 7MW offshore wind power main shaft bearing is highly pricise, but now China has successfully developed this product for the first time.

Complete Information You Want to Know about 7MW Offshore Wind Power Main Shaft Bearings

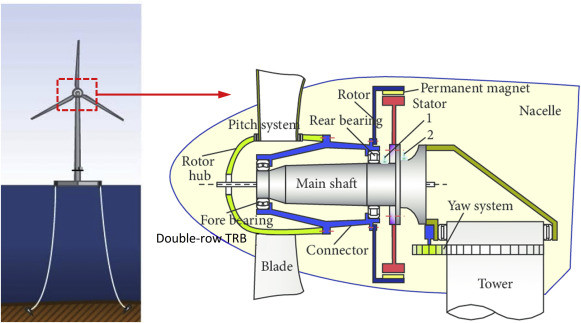

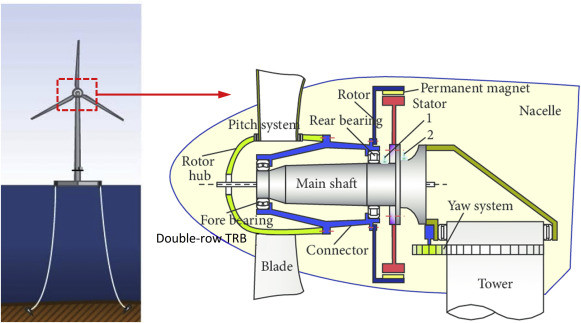

Brief introduction of offshore wind power shaft bearings

Due to the special working conditions of offshore wind turbines. And the main shaft bearing needs to be installed at a distance from the sea.

At a height of ten meters, bearing transportation, installation, and replacement is extremely inconvenient and expensive.

At the same time, the environment where offshore wind power bearings are located is very harsh. Including typhoons and air humidity.

Lead to corrosion, etc., so high performance, high reliability, and long life are essential for spindle bearings.

The quality it possesses.

At present, the wind power spindle bearings in use in China mainly rely on imports. The internationally renowned wind power spindle bearing manufacturers mainly include SKF of Sweden, Schaeffler of Germany, Timken of the United States, etc. And these brands dominate the market in the world.

Now China has successfully developed a 7MW offshore wind power main shaft bearing for the first time

The first domestic 7MW offshore wind power main shaft bearing was successfully developed. Recently, the 7MW offshore wind power main shaft bearing of the Institute of Shaft Research has successfully completed the installation and commissioning at the Yangjiang base.

In order to meet the strict requirements of working conditions, the technical team of the Shaft Research Institute has overcome many technical difficulties through a scientific selection of materials, simulation design, optimized manufacturing technology, special design and processing of cages, etc., and successfully developed a 7MW offshore wind power spindle bearing.

It uses two sets of tapered roller bearing arrangements with an outer diameter of 3100mm. It is also the largest and most precise wind turbine main shaft bearing in China.

The successful development of this product not only fills the gap in China's high-power wind turbine main shaft bearings but also breaks the long-term monopoly of other countries' bearing enterprises on the wind power main shaft bearing market.

Made in China made another big step forward!