- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

Complete Analysis on The Special Requirements for Bearings of wind Turbines 2021 [Works Quickly]

time2021/11/18

- Wind turbines are generally divided into doubly-fed, direct-drive, and hybrid types. The most widespread use of bearings is the traditional doubly-fed wind turbine.

Complete Analysis on The Special Requirements for Bearings of wind Turbines 2021 [Works Quickly]

Fan bearings in wind turbines

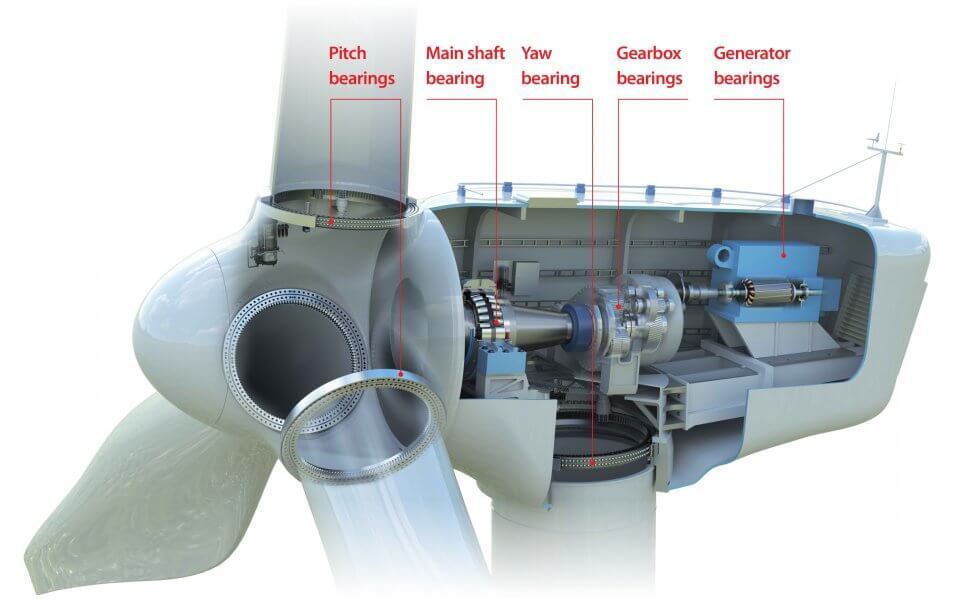

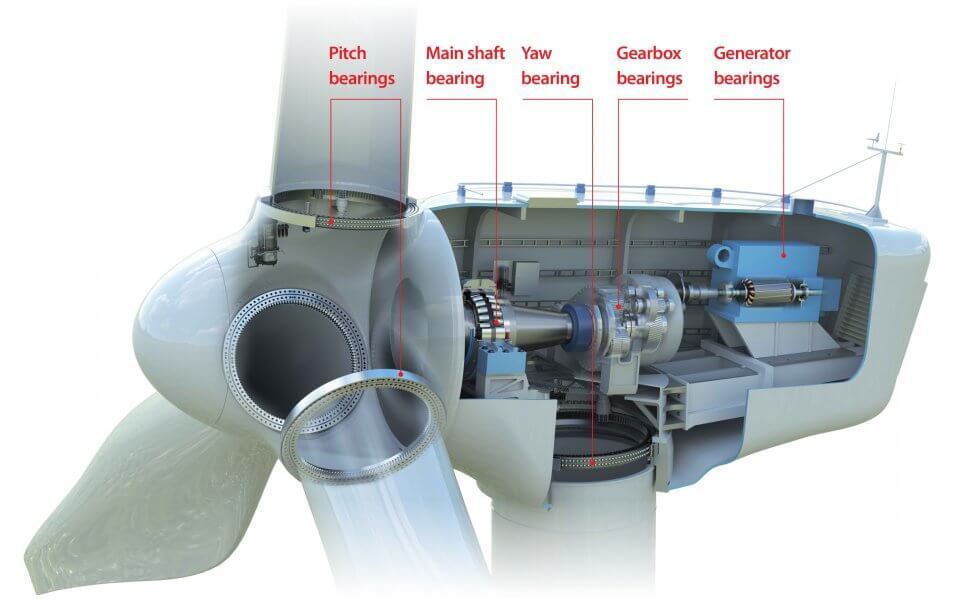

Wind turbines are generally divided into doubly-fed, direct-drive, and hybrid types. Various bearings have wide use in wind turbines. The most widespread use of bearings is the traditional doubly-fed wind turbine. One wind turbine Up to 32 sets of applied bearings. Therefore, the selection of bearings is very important to ensure the safe and stable operation of wind turbines.

Wind turbines are installed in areas with windy sand or relatively high humidity in the wild. The working conditions of wind turbine bearings are very harsh. And the temperature, humidity, and load need to be subjected to a wide range of changes.

In particular, the yaw and pitch bearings need to withstand large axial forces and overturning moments. And the gearbox bearings need to withstand huge shock loads during starting and braking. At the same time, the wind turbine gearbox bearings are required to have low friction when starting at low speeds.

Features of torque and high operating flexibility. Wind turbine bearings are generally divided into the following types: yaw bearings, pitch bearings, main shaft bearings, gearbox bearings and generator bearings. According to different bearing types, technical requirements are also different.

The following is an introduction to the two types of necessary bearings for fans.

Yaw, pitch bearing (fan bearing)

People generally design this type of bearing as an assembly. Using single-row four-point contact ball slewing bearings or double-row four-point contact ball slewing bearings, which should meet the following technical requirements:

According to the force characteristics of the wind turbine bearing, the yaw bearing adopts a small clearance. And the pitch bearing adopts a four-point contact ball bearing with zero clearance or a "negative clearance" design.

People need to specially design and process the channel to withstand large axial load and moment load. The yaw gear in the assembly should choose the appropriate material, modulus, tooth profile, and hardness to ensure the life matches with the driving gear. At the same time, targeted heat treatment measures must improve the strength of the tooth surface, so that the bearing has good wear resistance and impact resistance.

Because the fan needs to expose in the field. There are strict requirements on the sealing performance of the bearing. And the sealing form of the bearing must be optimized to ensure that the life of the bearing is the same as that of the fan.

Fans are installed at an altitude of more than 50m or even hundreds of meters, which is expensive for assembly and disassembly. Therefore, they must have very high reliability. Generally, we require a life span of 20 years. In addition, the bearing structure is sophisticated, so the design and manufacturing requirements are extremely high.

Gearbox bearing (fan bearing)

There are many types of gearbox bearings, such as deep groove ball bearings, cylindrical roller bearings, full complement cylindrical roller bearings, double row tapered roller bearings, spherical roller bearings, thrust spherical roller bearings, and four Point contact ball bearings. The bearings in the gearbox are mainly using the gear oil to lubricate in the gearbox.

There are more metal particles in the lubricating oil, which will obviously affect the life of the bearing. Therefore, a special heat treatment process needs to make the surface of the raceway have compressive stress and reduce the raceway.

Sensitivity to particle impurities improves bearing life. At the same time, it is also necessary to optimize the bearing structure according to the working conditions of the bearing, improve the processing technology of the bearing, and further improve the performance index of the bearing.