- Home

- About us

- Products

- Deep Groove Ball Bearing

- Ball Screw

- Self-aligning Ball Bearing

- Spherical Roller Bearing

- Thrust Aligning Roller Bearing

- Tapered Roller Bearing

- Thrust Ball Bearing

- Angular Contact Ball Bearing

- Thrust Roller Bearing

- Cylindrical Roller Bearing

- Pillow Block Bearing

- Machinery Equipment

- Thrust Conical Roller Bearing

- Bearing Cage

- Discount and Promotion all bearing

- Steel Balls

- Faqs

- News

- Certificate

- Contact us

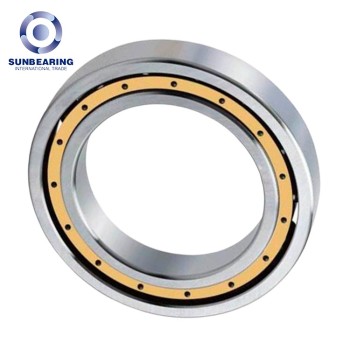

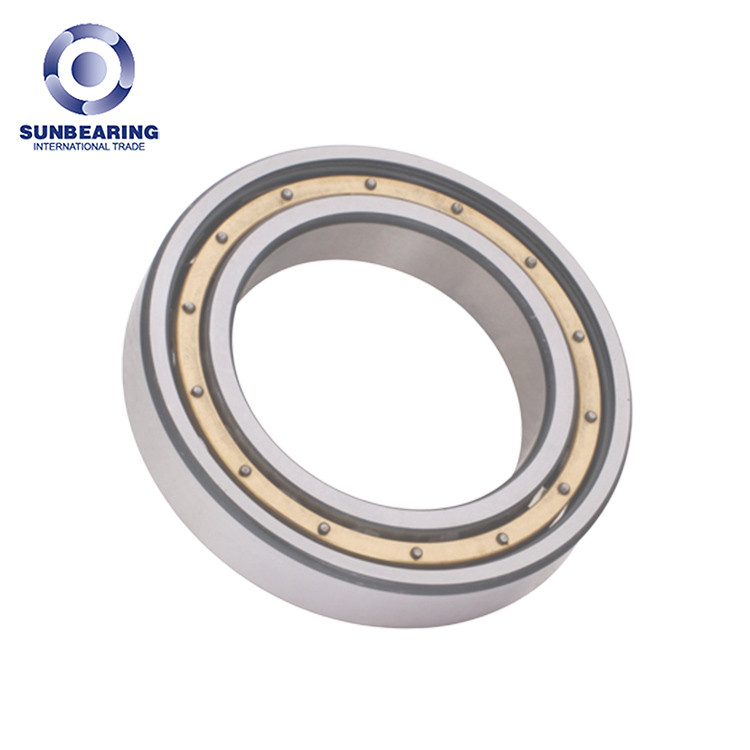

6044M C3 Open Deep Groove Ball Bearing with Brass Cage 220*340*56mm SUNBEARING

- group name

- Deep Groove Ball Bearing

- Min Order

- 1 piece

- brand name

- SUNBEARING Rolling Bearing Manufacturer

- model

- 6044M

- Nearest port for product export

- Dalian

- Delivery clauses under the trade mode

- FOB, CFR, CIF, DDP

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union

- update time

- Wed, 21 Sep 2022 16:31:27 GMT

Paramtents

Color Silver and yellow

Inner Diameter 220mm

Outer Diameter 340mm

Width 56mm

MOQ 1

Service OEM

Samples Free Sample

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

6044M Deep Groove Ball Bearing

Specification

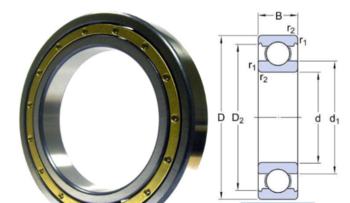

6044M Deep Groove Ball Bearing Description | |||

|---|---|---|---|

Specification | Dimensions | ||

Design Units | Metric | d-Bore Diameter | 220mm |

Structure | Ball Bearing | D-Outer Diameter | 340mm |

Weights | 15.5kgs | Precision Rating | P5 P6 P4 P2 P0 |

Cage Material | Brass Cage | Clearance | C2 C3 C4 C5 C0 |

Material | Chrome Steel GCR15 | ||

Ball Type | GCR15 Steel | H-Total Width | 56mm |

Seals Type | Open | Basic Load Ratings | |

Certificate | ISO9001:2008 | Cr Dynamic Load Rating | 242000N |

Feature | Having deep raceway grooves in close proximity to the balls enables a deep groove ball bearing to accommodate axial loads in both directions as well as radial loads, even at high speeds. | C0r Static Load Rating | 284000N |

Number of Rows | Single | Specifications/Environment | Standard |